It adopts Shenzhen Guodian GD series integrated automatic control panel and microcomputer hydraulic governor configuration.

Realize the standardization of unattended, less-attended automatic power generation and safe production

Launched in December 2019

1. The original state of the power station and the functional effect after the upgrade

Overview of the original status of the power station: impact-type units, 2 sets of 400kW brushless generators with installed capacity, dual-purpose AC governor for flashlights, semi-automatic diverter, on-site control panel has been in operation for nearly 15 years, and some safety hazards on site: The speed governor is an AC motor for speed regulation. After the large grid is adjusted, the voltage at the terminal of the machine is unstable or the water cannot be turned off under the condition of power failure, which causes the important problem of the unit flying, and the limit of the AC governor is not good. The operation is cumbersome and complicated: the grid voltage cannot be automatically tracked before the excitation is connected to the grid, and the power factor cannot be adjusted frequently after the grid is connected to meet the assessment requirements of the power supply bureau. The on-duty personnel are labor intensive, and the grid connection speed is as slow as 3-6 minutes for a single start-up, which does not achieve the better power generation efficiency that the power station design should have. Through this equipment upgrade and transformation of the hydropower station, the main goals are to improve the automation level by 85%, improve the safety of equipment and personnel by 50%, and increase the power generation efficiency by 2%-15%:

Level of automation after upgrade:

A. Unattended operation with few people on duty, no human operation is required in the station. The whole start-up process is reduced from 3-5 minutes to 30 seconds-1 minutes, the start-up time is shorter, a lot of water waste is reduced over time, and the number of operators is reduced. After the transformation is completed, only one person on duty will be reserved for the first shift of the power station for normal inspection and security work. The remote monitoring is located in the next-level power station, and it is equipped with a computer to remotely manage and monitor the operation of the equipment.

B. Several power generation operation modes suitable for power station automation,

1. Smart power generation mode: Automatically detect the water level of the front pool, generate more power according to the high water level, less power generation when the water level is low, and multi-unit collaborative power generation work mode, automatically start and stop according to the strategy or the actual requirements of the power station to achieve the optimal power generation work mode, indirectly increase the water level to generate electricity and increase the efficiency of the power station. (Workflow of automatic power generation: automatic detection of the water level in the front pool, automatic opening of the governor, automatic excitation at a reasonable frequency, automatic tracking of the grid voltage for the excitation, automatic detection of grid connection at the same time, and automatic adjustment of the excitation after grid connection according to the assessment requirements of the power supply bureau. It can automatically adjust the active power according to the water level, monitor and protect the electrical quantities such as current, voltage and frequency in the whole process, automatically trip when shutdown, automatically reduce water, automatically demagnetize, and automatically turn off the governor).

2. The user can set the target power of the power generation by himself: the target power can be set remotely with the computer in the central control room, and it will automatically start, automatically excite, automatically connect to the grid, and automatically send to the target power set by the owner. At the same time, the station can simply press the potentiometer knob to adjust the power to set the target power to run automatically. (Workflow for setting target power automation: automatic opening of the governor, automatic excitation at a reasonable frequency, automatic tracking of the grid voltage for the excitation, automatic detection of the grid connection at the same time, automatic adjustment of the reactive power after the grid connection, and automatic adjustment of the reactive power according to the assessment requirements of the power supply bureau, the whole process Monitoring and protection of electrical quantities such as current, voltage, frequency, automatic tripping at shutdown, automatic water reduction, automatic demagnetization, automatic shutdown of the governor).

3. Adjust the power by the potentiometer, which refers to manually adjusting the external knob potentiometer to set the target power to generate electricity.

4. Manual power adjustment, that is, adding and subtracting water by manual button to adjust the power generation.

5. Computer remote target opening: set the target opening by remote communication to generate electricity.

6. Power stations that are assessed during peak-valley period and peak-valley period can flexibly set up timed power generation and time-based power generation to maximize power generation benefits.

7. This automation panel also designs a set of semi-automatic power generation system operation as a backup power generation scheme in case of abnormal automatic operation.

Increase the safety of plant operation:

C. When the unit automatically controls the power generation and shuts down in an abnormal situation, the automatic system can give an alarm by an electric bell and a computer background alarm to the central control room to notify the on-duty personnel.

D. The turbine governor and the diverter are upgraded to microcomputer hydraulic governors, which have stored energy, and can guarantee more than 5 reliable shutdowns in the event of power failure in the power station, ensuring the safety of the power station and avoiding the speed of the unit.

E, real-time monitoring of main transformer temperature. If the temperature is too high, it will give an alarm or the temperature exceeds the limit and stop

F. It can manually start black when the big network has no power, and provide 10KW of self-generated and self-used electricity for living and lighting.

G. When the power station is connected to the broadband network, it can realize remote monitoring and control on the computer and mobile phone. The operation and control personnel need to obtain hierarchical authorization rights, and the power generation data is rich. In the case of abnormal shutdown of the power station, the administrator can be notified on the mobile phone. .

Photo of the electrical control part of the hydropower station before renovation

(Photos of power plant governor and diverter before renovation)

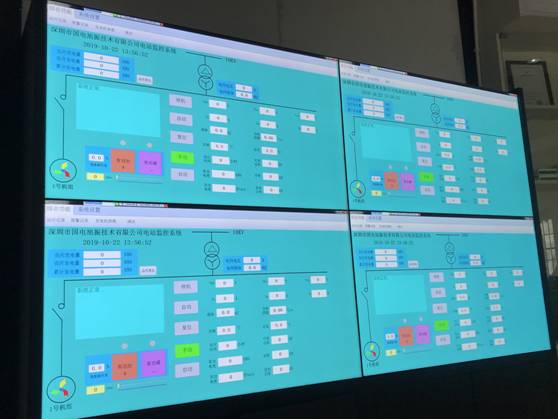

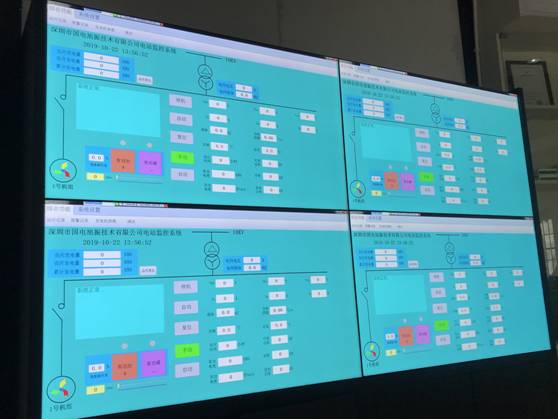

Photo of integrated automatic control screen of Shenzhen Guodian Automation GDK-B hydropower station after renovation

(Refer to the photos of the power plant governor and diverter after the transformation)

Photo of remote monitoring and control monitoring platform of computer and mobile phone.